Disposable sheets are a ubiquitous convenience in various industries and daily household use, offering a practical solution for hygiene, cleanliness, and convenience.

These sheets, designed for one-time use, find applications in medical settings, hospitality, beauty salons, households, and more. Understanding the materials used in their production sheds light on their versatility and functionality.

One of the primary materials employed in the manufacturing of disposable sheets is paper. Typically derived from wood pulp or recycled paper, paper-based disposable sheets encompass a wide range of products, including tissue paper and paper towels.

Their lightweight nature and absorbent properties make them ideal for tasks requiring quick cleanup or hand drying. Moreover, paper-based disposable sheets are often cost-effective and biodegradable, aligning with sustainability goals in various industries.

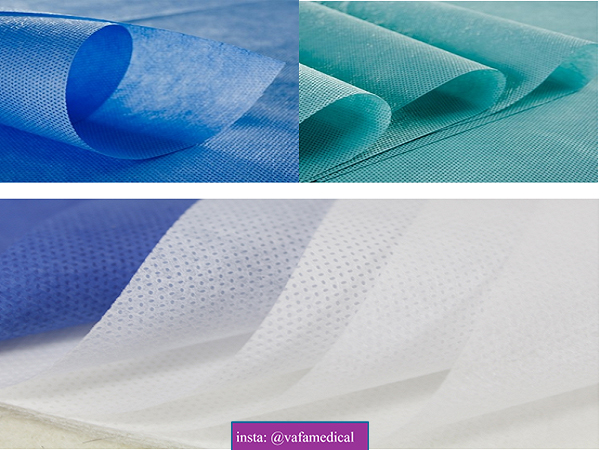

Non-woven fabrics represent another common material used in disposable sheet production. These fabrics consist of synthetic fibers bonded together through mechanical, chemical, or thermal processes.

Materials such as polypropylene, polyester, or nylon are frequently utilized in non-woven disposable sheets.

This fabric type offers advantages such as durability, tear resistance, and fluid repellency, making it suitable for medical drapes, surgical gowns, cleaning wipes, and protective covers.

Plastic materials play a crucial role in the production of certain disposable sheets, particularly those requiring waterproofing or barrier properties.

Polyethylene and polypropylene are commonly employed in plastic disposable sheets, providing impermeability to liquids and protection against spills or contaminants.

Plastic sheets find applications in medical settings for covering surfaces, in food service for wrapping and preserving items, and in households for various cleaning and protection purposes.

In recent years, there has been a notable shift towards the use of biodegradable materials in disposable sheet manufacturing. Materials such as bamboo, cornstarch, and other plant-based fibers offer an eco-friendly alternative to traditional disposable sheet materials.

These biodegradable sheets decompose naturally, reducing environmental impact and addressing concerns about plastic pollution.

As sustainability becomes increasingly important to consumers and businesses alike, the demand for biodegradable disposable sheets continues to grow.

In conclusion, disposable sheets are made from a diverse range of materials, each offering unique properties and advantages.

From paper-based products for everyday use to non-woven fabrics for medical applications and biodegradable alternatives for eco-conscious consumers, the materials used in disposable sheet manufacturing reflect innovation, functionality, and environmental awareness.

The choice of material for disposable sheets depends on factors such as intended use, performance requirements, cost considerations, and environmental impact.

Manufacturers carefully select materials to ensure that disposable sheets meet the specific needs of various industries and consumers while also aligning with sustainability goals.

Furthermore, advancements in material science and manufacturing processes continue to drive innovation in disposable sheet production.

Efforts to improve durability, absorbency, biodegradability, and other key properties contribute to the evolution of disposable sheet materials.

Additionally, collaborations between industries, researchers, and environmental advocates foster the development of more sustainable alternatives and practices in disposable sheet manufacturing.

In summary, disposable sheets are an essential aspect of modern hygiene and convenience, serving diverse purposes across industries and households.

By understanding the materials used in their production and embracing sustainable practices, we can enhance the functionality of disposable sheets while minimizing their environmental footprint.