Disposable bed sheets are essential in various industries, including healthcare, hospitality, and personal care.

The price of these sheets and the distribution strategies of manufacturers play significant roles in ensuring they are accessible and affordable.

This article explores the factors influencing the price of disposable sheets and how factories manage their production and distribution to meet global demand.

Understanding the Price of Disposable Bed Sheets

The price of disposable bed sheets is influenced by several key factors:

- Material and Composition

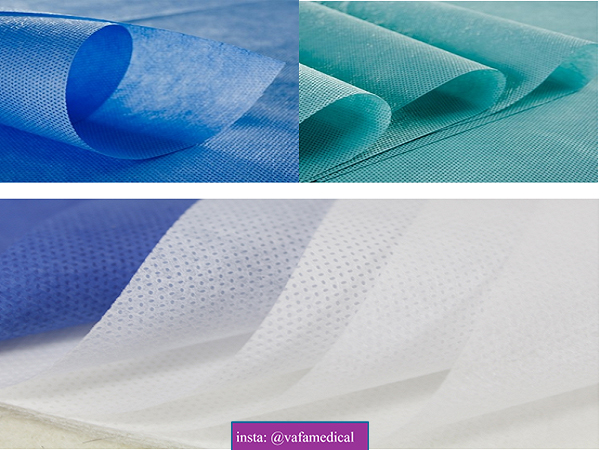

- Non-Woven Fabric: The most common material used, non-woven fabric, is lightweight, breathable, and cost-effective. The price for sheets made from this material generally ranges from $0.20 to $0.50 per sheet, depending on the thickness and additional features.

- PE Coating: Sheets with a polyethylene (PE) coating are waterproof, adding a layer of protection against liquids. This feature increases the cost, with prices typically starting at $0.30 per sheet.

- SMS Fabric: For environments requiring enhanced protection, SMS (Spunbond-Meltblown-Spunbond) fabric sheets are preferred. These sheets offer superior strength and fluid resistance, often priced between $0.40 and $0.70 per sheet.

- Thickness and GSM

- Thickness, measured in GSM (grams per square meter), directly impacts the durability and cost of the sheets. Higher GSM sheets are more durable but come at a higher price. For instance, a 40 GSM sheet may cost around $0.50, while a 20 GSM sheet might be $0.25.

- Size and Customization

- The size of the bed sheet also affects the price. Standard sizes like twin or queen are generally more affordable, while customized sizes or sheets with elastic edges may cost more due to the additional material and manufacturing complexity.

- Quantity and Bulk Pricing

- Purchasing disposable bed sheets in bulk can significantly reduce the per-sheet cost. Suppliers often offer discounts for large orders, with savings of up to 30% depending on the quantity. For example, a bulk order of 10,000 sheets might reduce the price from $0.50 to $0.35 per sheet.

- Brand and Supplier Reputation

- Established brands may charge a premium for their products due to their reputation for quality and reliability. However, lesser-known brands or new suppliers might offer competitive pricing, particularly for large orders, to attract customers.

Major Production and Distribution Strategies of Factories

The production and distribution of disposable bed sheets involve complex logistics to ensure a steady supply chain and meet global demand. Here’s an overview of how factories manage these processes:

- Production Capacity

- High-Volume Production: Leading factories are equipped with high-capacity machinery capable of producing millions of sheets per month. This scale of production helps keep costs low and meet large orders from clients in healthcare, hospitality, and other industries.

- Automated Manufacturing: Automation plays a crucial role in the production of disposable bed sheets. Automated systems streamline the cutting, coating, and packaging processes, reducing labor costs and minimizing errors, which in turn lowers the overall product cost.

- Quality Control

- Standard Compliance: Factories adhere to strict quality control measures, ensuring that each batch of sheets meets industry standards such as ISO certification or FDA approval for medical use. Regular inspections and testing are conducted to maintain product quality.

- Custom Quality Options: Some factories offer custom production runs where clients can specify the GSM, material composition, and additional features like antimicrobial treatments. These custom orders are subject to rigorous quality checks to ensure they meet the client’s specifications.

- Global Distribution Networks

- Direct Distribution: Many factories manage their distribution directly, shipping products from the manufacturing site to clients worldwide. This direct approach allows for better control over logistics and can reduce lead times.

- Partnerships with Distributors: To reach a broader market, factories often partner with local and international distributors. These partnerships enable faster delivery times and help the factory maintain a consistent presence in various regions.

- Online Sales Channels: With the rise of e-commerce, many factories have expanded their distribution networks to include online sales platforms. This strategy allows factories to reach smaller businesses or individual customers directly, offering smaller order quantities at competitive prices.

- Sustainability Practices

- Eco-Friendly Production: In response to growing environmental concerns, some factories have adopted sustainable manufacturing practices. This includes using recyclable or biodegradable materials and reducing energy consumption during production. While these practices can increase the cost of production, they appeal to environmentally conscious consumers.

- Waste Management: Efficient waste management is another critical aspect of sustainable production. Factories are increasingly focusing on minimizing waste generated during the manufacturing process, which not only benefits the environment but also reduces production costs.

- Lead Time and Delivery

- Optimized Lead Times: Factories strive to minimize lead times by maintaining an efficient production schedule and strong relationships with suppliers. Quick turnaround times are essential, especially for large orders or clients in industries where timely delivery is critical.

- Flexible Delivery Options: Depending on the client’s needs, factories offer various delivery options, from standard shipping to expedited services. Some factories maintain distribution centers in key regions to ensure rapid delivery and reduce shipping costs.

Conclusion

The price of disposable bed sheets is influenced by material choice, thickness, size, and order quantity. Understanding these factors can help you make an informed purchasing decision.

On the production side, factories employ advanced manufacturing techniques, strict quality control, and efficient distribution networks to meet global demand.

Whether you’re looking to buy in bulk or seeking specialized products, knowing the production and distribution strategies of manufacturers can help you find the best value for your investment in disposable bed sheets.