Spunbond fabric is increasingly popular in various industries, from healthcare to agriculture and beyond. This material, known for its durability, lightweight nature, and versatility, has become a staple in many applications. However, prices can fluctuate depending on factors like demand, raw materials, and production processes.

For businesses looking to secure spunbond fabric at competitive rates, it’s essential to stay updated on current market prices, trends, and reliable suppliers.

Here’s an in-depth look at spunbond fabric, including the factors influencing wholesale prices, the range of options available, and tips for finding the best deals on bulk orders.

1. Understanding Spunbond Fabric and Its Applications

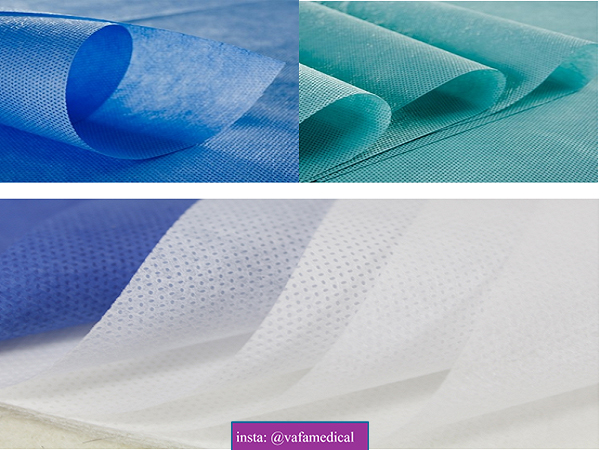

Spunbond fabric is a type of nonwoven material made from thermoplastic polymers, most commonly polypropylene. During the production process, polymer filaments are extruded, stretched, and bonded together, creating a web of material with impressive strength and flexibility.

Spunbond fabrics come in various weights, typically measured in grams per square meter (gsm), which determine their thickness and durability. Common uses for spunbond fabrics include:

- Medical Supplies: Masks, gowns, and disposable bedding.

- Agriculture: Crop covers and ground cover fabrics for weed prevention.

- Furniture and Upholstery: Mattress covers, furniture linings, and protective wraps.

- Packaging and Consumer Goods: Shopping bags, protective packaging, and more.

2. Factors Influencing Spunbond Fabric Prices

When looking at the wholesale price of spunbond fabric, several key factors come into play:

- Material Composition: Polypropylene is the most common material, but specialty versions, such as graphene-enhanced spunbond or biodegradable options, come at a premium due to their enhanced properties like antibacterial or eco-friendly attributes.

- Weight and Thickness: Heavier fabrics (like 90 gsm and above) generally cost more, as they provide additional durability for heavy-duty applications.

- Color and Customization: White spunbond fabric is the most cost-effective, but dyed or custom-printed fabrics may be priced higher due to additional processing.

- Order Volume: Bulk discounts are common, with significant price breaks often available for orders of 1,000 meters or more.

- Supplier Location and Shipping: Shipping costs and lead times can vary based on the supplier’s location and the destination of the order, impacting overall expenses.

3. Average Pricing for Wholesale Spunbond Fabric in 2024

Based on recent data, here’s an outline of current spunbond fabric prices for bulk orders:

- Standard White Polypropylene Spunbond: Priced between $1.80 to $2.30 per meter for wholesale orders, particularly in quantities exceeding 100 meters

Fabric UK

NWFabric.

- Graphene-Infused Spunbond: Typically higher in price due to additional antibacterial and durability features, priced around $2.50 to $3.00 per meter.

- Specialty Spunbond (e.g., Biodegradable or Colored): Ranges from $2.20 to $3.00 per meter, depending on customization and added treatments such as UV protection for agricultural applications

.

4. Top Sources for Wholesale Spunbond Fabric

To get the best prices, it’s essential to choose suppliers known for competitive pricing and quality control. Here are some popular options:

- Direct Manufacturers: Manufacturers in China and India often provide the lowest wholesale rates due to lower production costs and economies of scale.

- Specialized Nonwoven Fabric Suppliers: Many suppliers focus exclusively on nonwoven materials, which can help with both product selection and pricing competitiveness.

- Online Wholesale Marketplaces: Platforms like Alibaba and Global Sources allow buyers to compare rates from various suppliers, making it easier to find bulk deals and negotiate directly.

5. Benefits of Buying Spunbond Fabric in Bulk

For businesses that regularly use spunbond fabric, purchasing in bulk has multiple benefits:

- Cost Savings: Bulk purchases often come with lower per-unit costs, and suppliers may offer additional discounts or free shipping for large orders.

- Consistent Quality: Buying from the same supplier helps maintain consistency in quality, as products are often manufactured in batches.

- Supply Assurance: Having a stock of fabric on hand reduces the risk of supply chain disruptions, especially during high-demand periods like public health emergencies.

6. Tips for Securing the Best Wholesale Prices

- Negotiate with Suppliers: Don’t hesitate to negotiate with suppliers, especially for orders above the standard MOQ (Minimum Order Quantity).

- Monitor Market Trends: Prices for polypropylene, a key raw material in spunbond production, can vary with oil prices. Keep an eye on these trends to time purchases effectively.

- Consider Supplier Proximity: While overseas suppliers may offer lower prices, factoring in shipping costs and lead times is crucial for budgeting.

7. Spunbond Fabric and Its Future Market Trends

The spunbond fabric market is expected to grow, driven by demand in medical and environmental sectors. Innovations in eco-friendly spunbond options, such as biodegradable and recyclable fabrics, are gaining traction.

As businesses aim for sustainability, opting for environmentally friendly materials could impact pricing but also align with consumer preferences for greener products.

8. Quality Control and Certifications

When sourcing spunbond fabric, quality control is essential. Look for suppliers who offer certifications like ISO, SGS, or OEKO-TEX, which indicate that the fabric meets safety and environmental standards. Additionally, ask for sample tests before committing to large orders to ensure the material’s performance and suitability.

9. Key Takeaways

- Understand Your Needs: Choose a spunbond fabric that fits your application—consider factors like weight, color, and additional treatments.

- Buy in Bulk: For long-term savings and reliability, wholesale purchases are often the best option.

- Stay Informed: Keep track of market trends, raw material costs, and supplier locations to optimize your purchasing strategy.

Conclusion

Staying informed about the latest prices and trends in the spunbond fabric market can save your business both time and money.

Whether you’re looking for standard polypropylene fabrics or specialized options like graphene-infused spunbond, understanding the factors that affect pricing and sourcing the best supplier can help you secure high-quality materials at competitive rates.

For those interested in sustainable practices, eco-friendly spunbond options are also on the rise, allowing businesses to meet consumer demand for environmentally responsible products.

By following these guidelines, you can ensure your business stays ahead in sourcing quality spunbond fabric while optimizing costs and maintaining supply stability.